Welcome to

Temperature Select Air LLC

Your Trusted Heating and Cooling Experts

We Proudly offer a wide array of air conditioning, refrigerating , ventilating and heating services in Aurora, CO.

Expert Technicians

Skilled professionals with extensive experience in HVAC systems, ensuring high-quality service and reliable solutions.

Flexible Scheduling

Convenient appointment options that accommodate your busy life, making it easy to get the services you need when you need them.

Transparent Pricing

Clear and upfront cost estimates without hidden fees, allowing you to understand your expenses before committing to services.

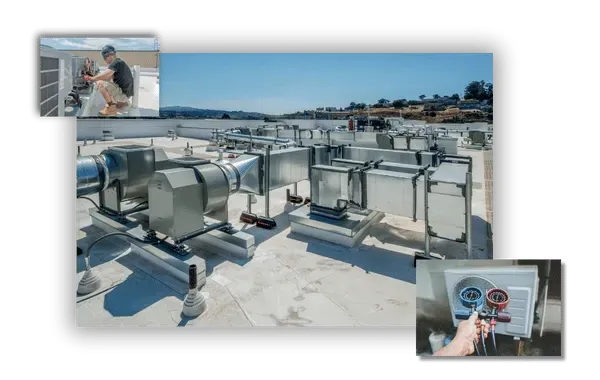

Energy-Efficient HVAC Specialists

Professionals at HVAC Temperature Select Air LLC who focus on installing, maintaining, and optimizing heating and cooling systems designed to reduce energy consumption. They provide tailored solutions that enhance comfort while lowering utility bills, contributing to a sustainable environment.

Schedule Free Appointment

Get Your Estimate

Brands we working with

Our Services

We are proud of the top-quality services that we provide our customers with guaranteed satisfaction. Our team continually strives to offer you the greatest solutions. Your vision is our mission!

What WE DO

We are a hub of solutions you are looking for.

Our Services include:

HVAC Repair Service

HVAC Maintenance

Mini Split AC Service

HVAC Installation

Heating Service

Heating Repair

Ventilation Contractor

Commercial Refrigeration Service

How We Works

You can see how we operate to complete our mission and fulfill our vision of leading the industry. Here is how we work.

Virtual Consultation

Our HVAC experts provide customers with virtual consultation to dive deep into the customer preference and choice of work.

Proper Scheduling

We schedule the service day to ensure customer convenience and deliver professionalism and excellence to your project.

Accurate Planning

After learning about your preference, our team devises a complete plan of project timeline to yield the results of your choice.

On-time Arrival

We have never been untimely in our operations and always reach the project site before time to start and complete the job within the ideal timeframe.

Reliable Workmanship

We assess the condition of your HVAC system and identify the defective components to arrange necessary repairs. We also install the system perfectly!

Work Completion

Our team goes above and beyond to meet your specific needs, and we do not compromise on our high service standards that never wane.

Testimonials

100% Money Back Guarantee

At Temperature Select Air, we offer a 100% Money Back Guarantee on all our HVAC services. Your satisfaction is our top priority, and if you're not completely happy with our work, we’ll either fix it or refund your money—no questions asked. Trust us for reliable, efficient heating and cooling solutions, risk-free!

Frequently Asked Questions

What services does Temperature Select Air offer?

Temperature Select Air provides heating, ventilation, and air conditioning (HVAC) services, including installation, maintenance, and repair for residential and commercial systems.

How can I schedule a service appointment?

You can schedule an appointment by calling us directly at our office or using the online booking feature on our website.

Do you offer emergency HVAC services?

Yes, we offer 24/7 emergency HVAC services to ensure your comfort is never compromised.

How can I maintain my HVAC system?

Regular maintenance is key! We recommend scheduling seasonal check-ups and replacing filters every 1-3 months. Our team can provide maintenance plans tailored to your needs.

How can I improve my home’s energy efficiency?

Consider upgrading to a programmable thermostat, sealing ducts, and ensuring proper insulation. Our team can provide an energy audit to identify specific improvements.

Innovation

Fresh, creative solutions.

Integrity

Honesty and transparency.

Excellence

Top-notch services

Copyright 2025. Roofers Edge. All Rights Reserved.

Innovation

Fresh, creative solutions.

Integrity

Honesty and transparency.

Excellence

Top-notch services

Copyright 2025. Roofers Edge. All Rights Reserved.